-

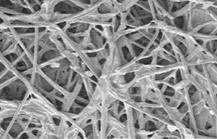

- Ordinary wood pulp fiber filter materialFeature: high air permeability, microporous structure, great intensity, and low cost.

-

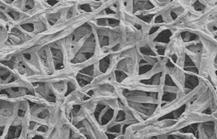

- Non-plant-based fiber filter materialFeature: high plasticity, high tear resistance, high moisture resistance and great anti-aging properties.

Non-plant fibers greatly improve the moisture resistance, bursting strength and stiffness of filter material, which make it more suitable for humid environments.

-

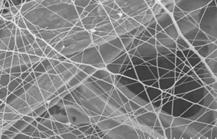

- Nano fiber based filterFeature: the application of nano materials greatly improves the filtering efficiency of wood pulp filter materials, and its great dust removal efficiency helps to extend the filter’s service life.

- Home

- Customized Filter

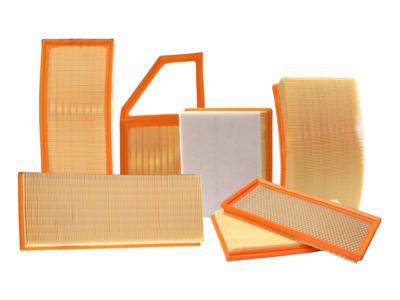

The true strength of SL Filter lies in our research and development capabilities. Thanks to our development abilities, we can provide customers with fully customized air filters, oil filters, diesel filters, air-oil separators, hydraulic filters, and so on. These products will be perfectly tailored to whatever application necessary. We have created custom filters for passenger cars, commercial vehicles, construction machinery, and air compressors. Simply provide us with product drawings or samples and we will review it immediately.

The filter media is the most important factor in the design of filtration products as certain types of filter paper are better suited for specific applications. We can provide you with a comprehensive selection of advanced filtration materials according to your requirements.

Here are some of our filter materials. Just let us know your requirements and we will provide you with a complete customization plan.- Neutral packing

- Color box packing

- White box packing

- Bulk packing

- Provide basic information

1) Explain the technical requirements of products

2) Provide product samples

3) Provide product drawings

4) For some special products, customers can provide us with the main raw material, and we can begin co-production. - Special requirements

We will meet all possible special requirements of customers, such as filter material, product operating environment and related machinery.

- Confirm sample

We have professional engineers who will review the product samples according to the requirements. After communication with customers, we will send samples to them according to their demands. Customers confirm samples and then we will begin production.

- Delivery

The regular product delivery date is 3-35 days after the receipt of deposit. The specific time will depend on the actual product.

If you need customized products, usually the delivery time is 35-40 days, and if you need mold fabrication, then the delivery date is typically 40-45 days.